The digitally driven change in industrial production demands stronger networking and more intelligent information at all production levels. With the fischertechnik Learning Factory 4.0, these digitalisation activities can be simulated, learned and applied on a small scale before they are implemented on a large scale. A highly flexible, modular as well as cost-effective and robust training and simulation model that can be put to exceedingly good use.

The fischertechnik learning environment is used for learning and grasping Industry 4.0 applications in vocational schools and training as well as for use in research, teaching and development at universities, in companies and IT departments. The simulation maps the ordering process, the production process and the delivery process in digitalised and networked process steps.

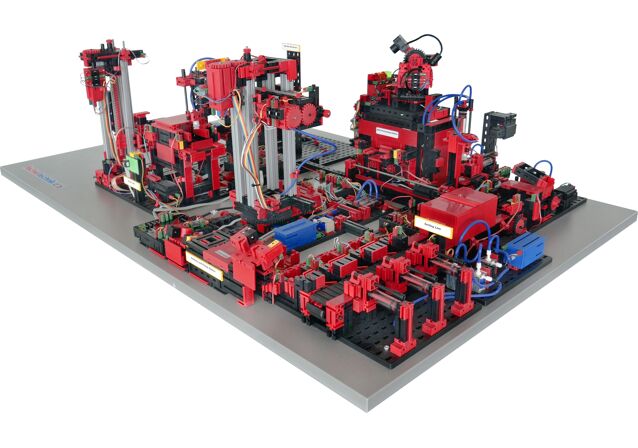

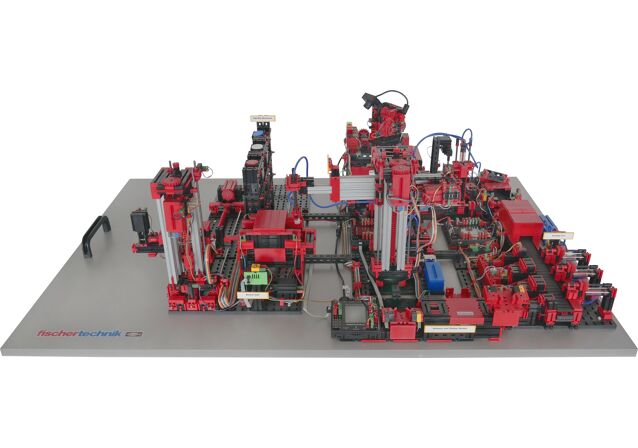

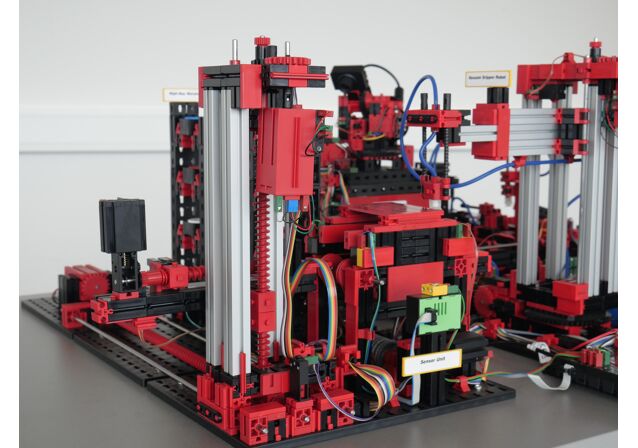

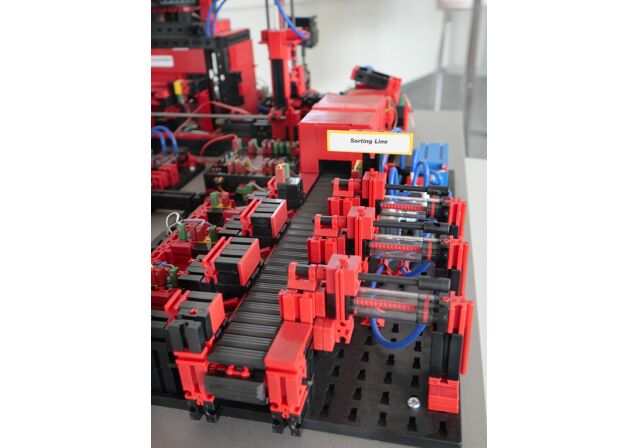

Factory environment

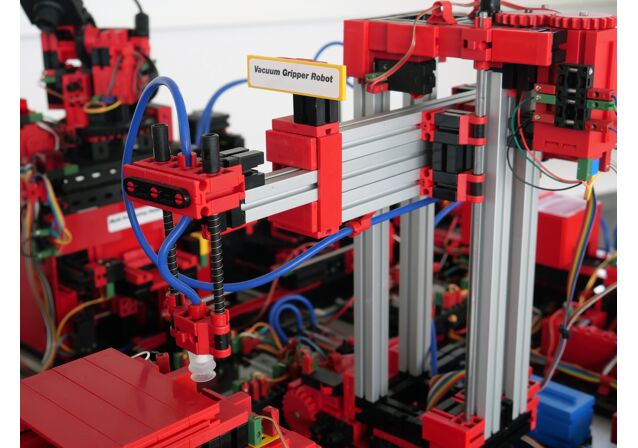

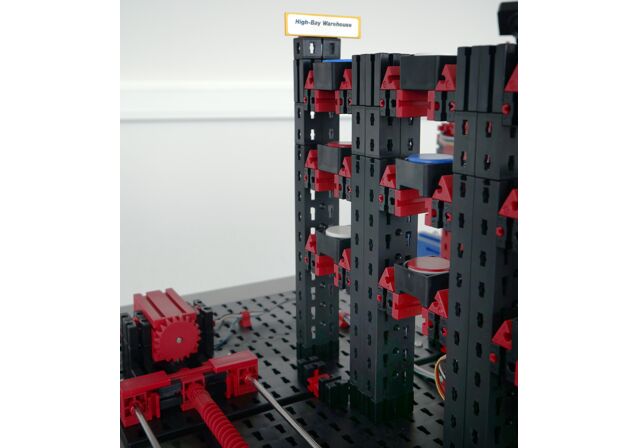

This consists of the factory modules storage and retrieval station, vacuum suction gripper, high-bay warehouse, multi-machining station with kiln, a sorting line with colour recognition, an environmental sensor and a swivelling camera. After an order has been placed in the dashboard, the workpieces pass through the respective factory modules and the current status is immediately visible in the dashboard. The integrated environmental sensor reports values for temperature, humidity, air pressure and air quality. The camera's vertical and horizontal swivel range allows it to see the entire plant, making it suitable for web-based remote monitoring.

The individual workpieces are immediately visible in the dashboard.

The individual workpieces are tracked by NFC (Near Field Communication): each workpiece receives a unique identification number (ID). This enables the current status of the workpieces in the machining process to be traced and visible.

The workpieces are tracked by NFC (Near Field Communication).

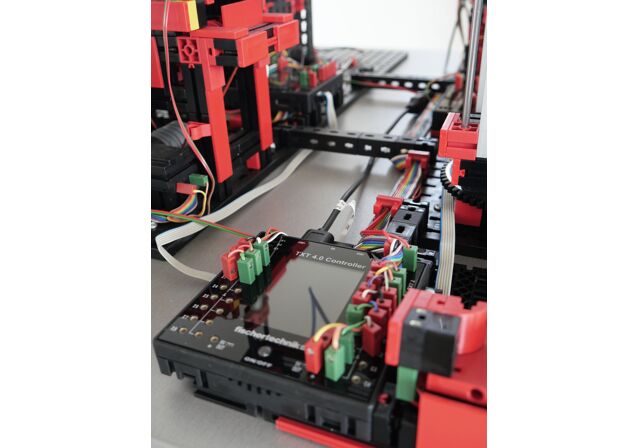

Control

The Learning Factory 4.0 is controlled by the fischertechnik TXT 4.0 controllers on a 9V basis, of which six are installed. These are connected within the factory according to the master-slave principle and communicate via an internal bus system. The complete performance data of the TXT 4.0 controller can be viewed at the TXT 4.0 Controller, here are the most important features:

- Processor: Arm® dual Cortex®-A7 650 MHz + Cortex®-M4

- Memory capacity: 512 MB DDR3 RAM, 4 GB eMMC

- Memory expansion: micro SD card slot

- Colour touch display: 2.4", 320x240 pixels, capacitive (allows swipe gestures)

- flat design, dimensions: 90x90x17.5mm

- 8 universal inputs: digital/analogue 0-9VDC, analogue 0-5 kΩ

- 4 fast count inputs: digital, frequency up to 1kHz

- 4 motor outputs 9V/250mA (max. 1 A): Speed infinitely variable, short-circuit proof, alternatively 8 individual outputs e.g. for LEDs

- 3 servo outputs 5V (max. 2A), short-circuit proof

- Combined Bluetooth / WLAN radio module: Bluetooth 5.0 (BR, LE & EDR), WLAN dual band 2.4 GHz and 5 GHz 802.11 a/b/g/n

- USB 2.0 client: mini USB socket for connection to PC

- USB host interface: USB-A socket e.g. for fischertechnik USB camera or USB sticks

- Camera interface: via USB host, Linux camera driver integrated in operating system

- 2x pin header 6-pin: for expansion of inputs and outputs (up to 9 TXT 4. 0 controllers can be coupled) as well as I²C interface

- Integrated loudspeaker for playing sounds (WAV files

- Linux-based open-source operating system, firmware update via cloud, USB stick or micro SD card

- Programming with ROBO Pro Coding (graphical and Python), C/C++ compiler (not included)

- further programming options via REST interface. Available output voltages 9V, 5V and 3.3V. Power supply: 9V DC socket 3.45 mm, or fischertechnik sockets 2.5 mm (for battery pack). Incl. USB connection cable and extension cable 6-pin.

Software: ROBO Pro Coding / Python programming interface

The software application is written in ROBO Pro Coding or in Python and is loaded onto the controller